Description

Screw Compressors With Inverter

Puma Screw Compressors are designed for industrial operations, offering power from 30 HP to 430 HP, low noise levels, and high performance.

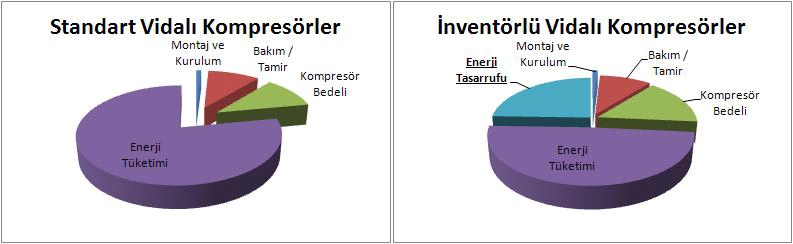

Up to 35% Energy Savings

Screw Group

The screw groups of Puma Screw Compressors are manufactured by a globally recognized professional screw group manufacturer. These screw groups are highly efficient, produced under full quality control, and have the lowest maintenance costs. The screw groups used in Puma Screw Compressors are produced with high precision using advanced machinery. They include high-efficiency rotors with a large compression area, offering low operating costs. High-quality bearings with high load-bearing capacity are utilized.

Air Intake System

A safe and economical air intake system is provided through a professionally designed intake valve. The specially designed air filter prevents dust and other harmful particles that could damage the screw group, thereby improving the quality of compressed air. The panel filter in the machine offers pre-filtration before the air intake filter.

Air & Oil Filtration System

The specially designed Spin-On Separator allows easy removal and replacement via a screwing method, minimizing service time. This separator reduces the oil content in compressed air to 1-2 ppm. Effective air-oil separation improves compressed air quality and minimizes malfunctions in connected devices.

Cooling System

Durable combi-block radiators that operate smoothly under all conditions have been used. The radiators, designed with a large cooling area, ensure efficient cooling even at high ambient temperatures.

Thermostatic Valve

The specially designed thermostatic valve ensures the machine operates at optimal working temperatures, preventing water condensation caused by low temperatures. This extends the lifespan of bearings, oil, rotors, and other equipment.

Oil Filtration System

Easily removable and replaceable oil filters ensure efficient oil filtration, prolonging the lifespan of rotors, bearings, and other moving parts.

Control System

Puma Screw Compressors feature user-friendly and multifunctional electronic control panels. These panels display air pressure, oil temperature, total and loaded operating hours, and service hours. Additionally, the specially designed control system ensures complete safety.

Cabinet System

– Compact design provides minimal working space and ease of transportation.

– Electrostatic powder coating protects against impacts and rust.

– Special sound insulation reduces noise levels and prevents flammability.

– Fully opening side panels and compact design facilitate maintenance.

– A belt tensioning system allows easy intervention.

Safety System

– Main motor overcurrent protection system

– Fan motor overcurrent protection system

– High oil temperature protection system

– High-pressure protection system

– High-pressure safety valves

– Emergency stop button

– Fault and maintenance warning system

VIEW PRODUCT CATALOG

VIEW PRODUCT CATALOG

Reviews

There are no reviews yet.