Applications of Compressors

Industrial Applications

Air Compressors and Manufacturing Processes

Air compressors play an indispensable role in industrial manufacturing processes. Many machines used in factories require high-pressure air obtained from air compressors. These systems are used to increase the efficiency of manufacturing processes and optimize workflows. Compressors are especially crucial in automation systems and production lines. Robotic systems used in production processes operate through air compressors. Regular maintenance and proper usage of these systems are extremely important to ensure the continuity of production lines.

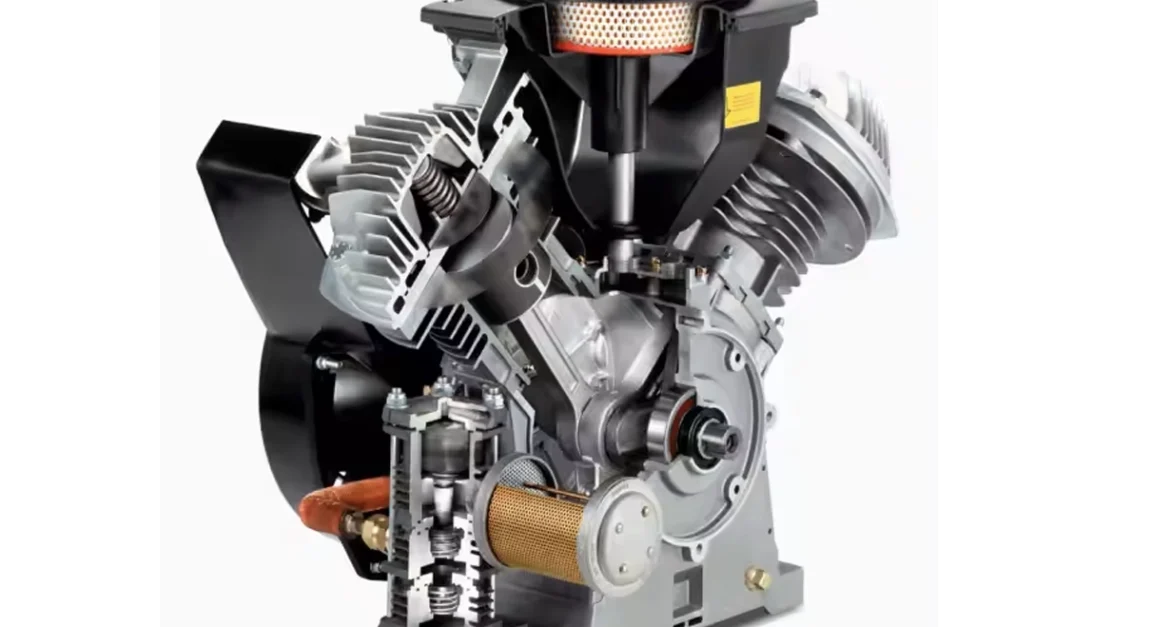

Operating Principle of Compressors

Air compressors take in air and compress it to store it under pressure. This compression process causes the air molecules to come closer together, resulting in a more concentrated energy source. Compressed air not only powers industrial machines but is also used in cooling and cleaning processes with high-pressure air. For example, compressed air is used to clean waste generated during production, which enhances workplace safety.

Different Types of Compressors

There are different types of air compressors in the industry, including piston, screw, and rotary compressors. Each type has its own advantages and disadvantages. Piston compressors are generally more cost-effective and ideal for short-term use. Screw compressors are designed for continuous use and offer higher efficiency. Additionally, rotary compressors are suitable for applications with low flow requirements. Choosing the most suitable type of compressor for industrial applications directly affects businesses’ costs and efficiency.

Use of Compressors in Agriculture

The Role of Air Compressors in Agriculture

The agricultural sector utilizes air compressors to enhance the effectiveness of various processes. Irrigation systems, agricultural machinery, and food processing stages often use air compressors. In agriculture, air compressors play a critical role in processes such as water distribution and soil aeration. This improves the quality and productivity of agricultural products.

Irrigation Systems and Compressors

In modern agricultural practices, irrigation systems are optimized with air compressors. Compressed air is used to operate irrigation systems and ensure the more efficient distribution of water. These systems are vital for enhancing agricultural productivity and conserving water. Furthermore, air compressors are also used in drip irrigation systems, ensuring water directly reaches plant roots.

Food Processing and Storage

In the food processing industry, air compressors play an essential role in product processing and packaging stages. Compressed air is used to enhance food safety and extend the shelf life of products. In the transportation of food products, air compressors play a critical role in maintaining hygiene in packaging processes and storage conditions. This is necessary for both consumer health and product quality.

Use of Compressors in the Automotive Industry

Vehicle Maintenance and Repair

In the automotive industry, air compressors are widely used in maintenance and repair processes. These compressors provide the necessary air pressure to clean and lubricate various parts of vehicles. This process is crucial for enhancing vehicle performance and extending their lifespan.

Pneumatic Tools and Compressors

Pneumatic tools are devices that operate with air compressors and are commonly used in vehicle maintenance. These tools offer the ability to work faster and more efficiently, improving the workflow in automotive service centers. For example, air guns, air cutting machines, and air sanders work with air compressors to achieve more effective results. Using these tools saves time and makes labor more efficient.

Safety of Compressors

The safe use of air compressors in the automotive industry is of great importance. Users should take necessary safety precautions before using compressors and perform regular maintenance on the equipment. This is critical for both workplace safety and the longevity of the equipment. Overheating, pressure fluctuations, or improper use of compressors can lead to serious accidents. Therefore, it is crucial for workers to receive training on the safe use of air compressors.

Use of Compressors in the Construction Industry

The Importance of Air Compressors in Construction

The construction industry is one of the most intensive areas for the use of air compressors. Compressors play a significant role in operating construction machines, tools, and equipment. This provides great advantages in speeding up construction projects and making the most efficient use of labor.

Applications of Compressors

In the construction sector, air compressors are commonly used for digging, drilling, and cutting operations. For example, pneumatic drills and air guns are indispensable tools in the construction process. These tools help to carry out tasks more quickly and effectively on construction sites. Additionally, air compressors are also used for cleaning construction machinery.

Construction Safety and Compressors

The safe use of air compressors in construction projects is of great importance. On construction sites, attention should be paid to regular maintenance and safe operation of compressors to ensure worker safety. Otherwise, accidents and injuries may occur. The use of air compressors in the construction industry requires careful attention to ensure job safety.

Use of Compressors in the Healthcare Sector

Medical Applications and Air Compressors

The healthcare sector is one of the critical areas where air compressors are used. Compressors are used to operate medical devices. Specifically, respiratory devices, anesthesia machines, and dental equipment rely on air compressors.

Operating Principle of Medical Equipment

Medical devices operate with high-pressure air, playing a significant role in patient care. For example, respiratory devices provide the necessary air to support patients’ respiratory functions. These types of equipment are crucial for improving the quality of life and enhancing treatment processes for patients.

Hygienic Use of Compressors

The hygienic use of air compressors in the healthcare sector is extremely important. In medical applications, the air produced by compressors must be sterile. Therefore, regular maintenance of compressors and the inspection of filter systems are crucial. This is an important step in ensuring patient safety and reducing the risk of infections.

Use of Compressors in the Food and Beverage Industry

Food Production Processes

In the food and beverage industry, air compressors play an important role in product processing, packaging, and storage. In these processes, compressed air is used to maintain hygiene and improve product quality.

Air Compressors in Packaging Systems

During the packaging of food products, air compressors are frequently used. Compressed air supports processes like shaping and sealing packaging. Additionally, air compressors play an important role in vacuum packaging systems. This ensures that food stays fresh and extends its shelf life.

Hygiene Standards and Compressors

In the food industry, it is essential to use air compressors in a way that meets hygiene standards. Compressed air is also used to clean tools that come into direct contact with food. Therefore, air compressors must undergo regular maintenance and be operated in hygienic conditions.

Use of Air Compressors in the Maritime Industry

Maritime Industry Applications

In the maritime industry, air compressors play a crucial role in the maintenance of boats and yachts, underwater research, and the operation of various marine vehicles. Compressors are used to enhance the performance of marine vehicles and speed up maintenance processes.

Boat Maintenance and Repair

In the maintenance of marine vehicles, air compressors are a great help in cleaning and lubricating operations. For example, compressed air is used during engine cleaning and underwater equipment maintenance. This is a critical step in enhancing the performance and extending the lifespan of marine vehicles.

Safety of Air Compressors

In the maritime sector, safety precautions must be followed when using air compressors. This ensures the protection of both workers and equipment. Regular inspection and maintenance of air compressors are essential to avoid accidents and ensure smooth operation.